|

|

IPC-7351 Padstack Naming Convention |

Post Reply

|

Page <1234> |

| Author | |

PLTcbv

Advanced User

Joined: 21 Aug 2012 Location: the Netherlands Status: Offline Points: 134 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08 Nov 2013 at 6:28am Posted: 08 Nov 2013 at 6:28am |

|

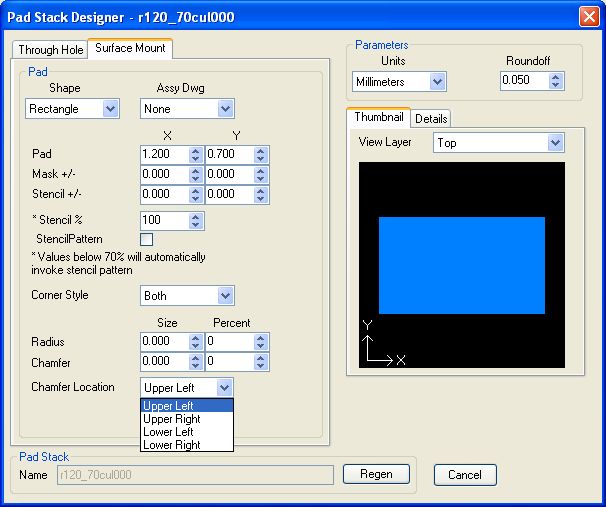

I have checked the latest version (2013.16) but the naming for the Chamfer Location is still not fixed.

Still "Lower Left" and "Lower Right". Should be according IPC "Bottom Left" and "Bottom Right".

|

|

|

|

|

|

|

|

chads108

Active User

Joined: 17 Oct 2012 Location: Plano, TX Status: Offline Points: 35 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Mar 2014 at 6:03am Posted: 20 Mar 2014 at 6:03am |

|

Any suggestions for naming multi-drill padstacks?

|

|

|

|

SteveD

Expert User

Joined: 30 Oct 2013 Location: San Diego Status: Offline Points: 240 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 23 Jun 2015 at 11:41am Posted: 23 Jun 2015 at 11:41am |

|

What is the terminal layer in a pad stack? And why do some components have it, and others do not?

|

|

|

|

Matthew Lamkin

Advanced User

Joined: 02 Oct 2012 Status: Offline Points: 284 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Oct 2015 at 2:17am Posted: 05 Oct 2015 at 2:17am |

|

I have someone asking a question about this.

To me it's obvious, the inner layer lands are always the same shape as the outer layer lands unless you deliberately change them to be something else, the default shape (unless there are overriding factors that require otherwise) is for the inner layer land to be circular. But it does not read as I have written it - it just reads conflicting. :) |

|

|

|

Tom H

Admin Group

Joined: 05 Jan 2012 Location: San Diego, CA Status: Offline Points: 6022 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Oct 2015 at 4:18am Posted: 05 Oct 2015 at 4:18am |

|

Since the beginning g of multilayer PCB layout back in the 1970's the outer layer Pin 1 pad shape was square to indicate the Polarity Marking because there was no silkscreen. Otherwise all pad stacks would be round throughout the entire PC board.

There was no need to take up valuable board real-estate with square corner pads on the inner layer because you cannot see them anyway. 10 years later when CAD tools started to become popular the trend continued and that is the way Pin 1 pad stacks are created. i.e.: there is no other use for outer layer square pads than to indicate polarity and that is the "Default Pad Stack". Rookie designers ask these types of legitimate questions and the old timers have to explain: "Because that's the way it's always been done" (even though it breaks a pad stack naming convention rule in order to simplify the pad stack name).  We're not going to break rank on this issue. We're not going to break rank on this issue. |

|

|

|

Matthew Lamkin

Advanced User

Joined: 02 Oct 2012 Status: Offline Points: 284 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Oct 2015 at 4:27am Posted: 05 Oct 2015 at 4:27am |

|

Cheers Tom,

So now I am being told your document should be changed as it is your document that is saying that they should be the same shape as on the outer layers. Which is contrary to both what you have explained and that the 2nd item suggests. They are either matching the outer layer shape or they are round. Inner Layer Land is the same shape as the outer layer land contradicts: The inner layer land shapes are Circular Because if the outer layer land is square and the inner layer land is the same shape as per the first default then it cannot be round as per the 2nd default. What is being suggested is that your statements in that are conflicting & hence confusing - perhaps the first one should not be used? |

|

|

|

Tom H

Admin Group

Joined: 05 Jan 2012 Location: San Diego, CA Status: Offline Points: 6022 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Oct 2015 at 4:38am Posted: 05 Oct 2015 at 4:38am |

|

I guess we'll have to change the document to clarify the rule. Thanks for the heads up.

A square pad on an inner layer is useless. |

|

|

|

Matthew Lamkin

Advanced User

Joined: 02 Oct 2012 Status: Offline Points: 284 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Oct 2015 at 4:39am Posted: 05 Oct 2015 at 4:39am |

Cheers Tom. |

|

|

|

jameshead

Expert User

Joined: 20 Mar 2012 Location: Oxfordshire, UK Status: Offline Points: 576 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 05 Oct 2015 at 5:45am Posted: 05 Oct 2015 at 5:45am |

|

Another example of padstyle of the top "layer 1" may be different to the inner and bottom layers is a TO-220 horizontal where you have a rectangular pad to connect with the heatsink of the device and have only a round pad on inner and the bottom layer.

I've interpreted the standard to have: r1599_1039r25o510xc580zc580h385 Rectangular 15.99 mm x 10.39 mm, radius 0.25 mm corners for a pad on layer 1, where the centre of the rectangular pad is off-set 5.1 mm from the centre of the hole. Hole size is 3.85 mm. Pads on inner layers and the bottom size is a round 5.80 mm. Not all CAD systems allow you do this easily though. |

|

|

|

AleksMK

New User

Joined: 31 Mar 2020 Status: Offline Points: 4 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 29 Apr 2020 at 6:50am Posted: 29 Apr 2020 at 6:50am |

|

Hi everyone, I have a question on the use of the special x modifier. This is it's definition: "x = Special modifier

used alone or following other modifiers for lands on opposite side to primary

layer land dimension" And later on there are three examples: mxc = Solder Mask

Opposite Side Circular

mx0 = Solder Mask Opposite Side No Solder Mask xc = Opposite Side Circular As the x-modifier is defined that it is following other modifier, is the last "xc" example wrong? Should it not be "cx"? I need to create a padstack, which will have a circular land patter on the bottom layer only 1.2mm in size, with a solder mask on the bottom layer only with 1.3mm opening and no bottom paste mask layer. Which of the following namings (or none?) will be the correct one for this padstack? 1. cx120mx130px0 2. xc120mx130px0 3. xc120xm130xp0 Thanks! Aleks |

|

|

|

Post Reply

|

Page <1234> |

| Tweet |

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |