|

|

Placement Courtyard Excess |

Post Reply

|

| Author | ||||||||||||||||||||||||||||

Tom H

Admin Group

Joined: 05 Jan 2012 Location: San Diego, CA Status: Offline Points: 5753 |

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Topic: Placement Courtyard Excess Topic: Placement Courtyard ExcessPosted: 07 Apr 2024 at 2:54pm |

|||||||||||||||||||||||||||

|

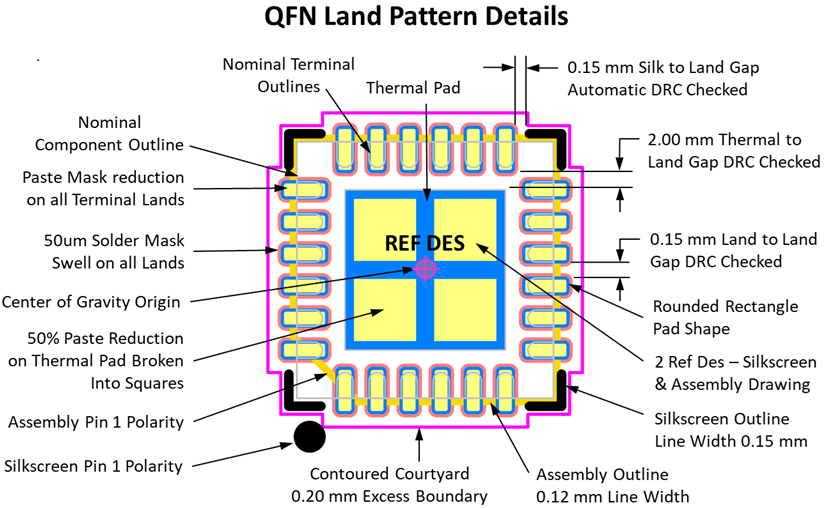

IPC-7351B refers to a 0.25 Courtyard Excess for Nominal Density Level. However, feedback from our customers indicate 0.20 Courtyard Excess works perfect. The Least Density Courtyard Excess is 0.10, Nominal 0.20 and Most is 0.40. There are 2 courtyard settings. One for the package body and one for the pads. The Package Body uses the Maximum package dimension.

Some Enterprise CAD tools turn the courtyard excess off to contour the courtyard to the maximum package dimensions. Then they use the courtyard for Placement Boundary or use the CAD tool rules for footprint to footprint spacing rules. The manufacturing zone is intended for assembly shops who need more area around the footprint pattern. Your assembly shop needs to communicate this information.  |

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

achico

New User

Joined: 10 Feb 2025 Status: Offline Points: 1 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 6 hours 17 minutes ago at 5:34am Posted: 6 hours 17 minutes ago at 5:34am |

|||||||||||||||||||||||||||

|

From IPC-7352 I found this information, is it correct? It seems to be different as to IPC-7351B referenced.

|

||||||||||||||||||||||||||||

| 0.50 mm | 1.00 mm | ||

| 0.25 mm | 0.50 mm | ||

| 0.20 mm | 0.25 mm | ||

| 0.75 mm | 1.25 mm | ||

| 0.50 mm | 1.00 mm | ||

| 0.25 mm | 0.50 mm |

Post Options

Post Options

Thanks(0)

Thanks(0)

Quote

Quote  Reply

Reply

Posted: 2 hours 37 minutes ago at 9:14am

Posted: 2 hours 37 minutes ago at 9:14am

Post Reply

|

|

| Tweet |

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |