FR4

Printed From: PCB Libraries Forum

Category: Training / Events

Forum Name: PCB Design Basics

Forum Description:

URL: https://www.PCBLibraries.com/forum/forum_posts.asp?TID=2234

Printed Date: 14 Feb 2026 at 5:51am

Topic: FR4

Posted By: silverlombard

Subject: FR4

Date Posted: 03 Oct 2017 at 8:02pm

|

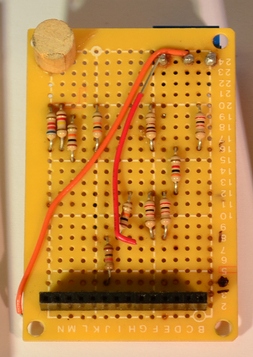

The base material, or substrate, is usually fiberglass. Historically, the most common designator for this fiberglass is “FR4”. This solid core gives the PCB its rigidity and thickness. There are also flexible PCB's built on flexible high-temperature plastic (Kapton or the equivalent). You will find many different thickness PCB's; the most common thickness for SparkFun products is 1.60 mm (0.063"). Some of our products: LilyPad boards and Arudino Pro Micro boards use a 0.80 mm thick board. https://cdn.sparkfun.com/assets/7/9/a/5/3/50d49bd5ce395f560c000002.jpg" rel="nofollow"> Cheaper PCB's and perf boards (shown above) will be made with other materials such as epoxies or phenolics which lack the durability of FR4 but are much less expensive. You will know you are working with this type of PCB when you solder to it - they have a very distictive bad smell. These types of substrates are also typically found in low-end consumer electronics. Phenolics have a low thermal decomposition temperature which causes them to delaminate, smoke and char when the soldering iron is held too long on the board. |