Rounded Rectangle Pad Shape

Printed From: PCB Libraries Forum

Category: PCB Footprint Expert

Forum Name: Questions & Answers

Forum Description: issues and technical support

URL: https://www.PCBLibraries.com/forum/forum_posts.asp?TID=1462

Printed Date: 13 Jan 2026 at 4:52pm

Topic: Rounded Rectangle Pad Shape

Posted By: Tom H

Subject: Rounded Rectangle Pad Shape

Date Posted: 05 Nov 2014 at 10:11am

|

IPC Land Pattern

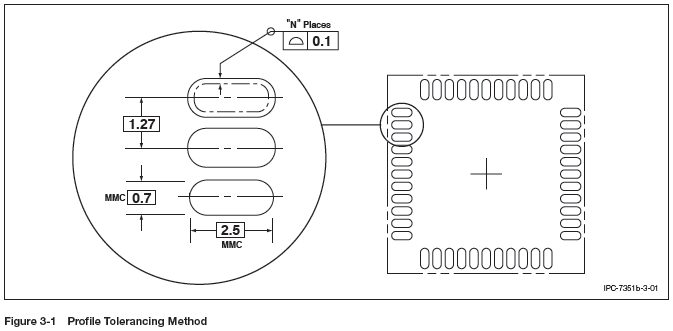

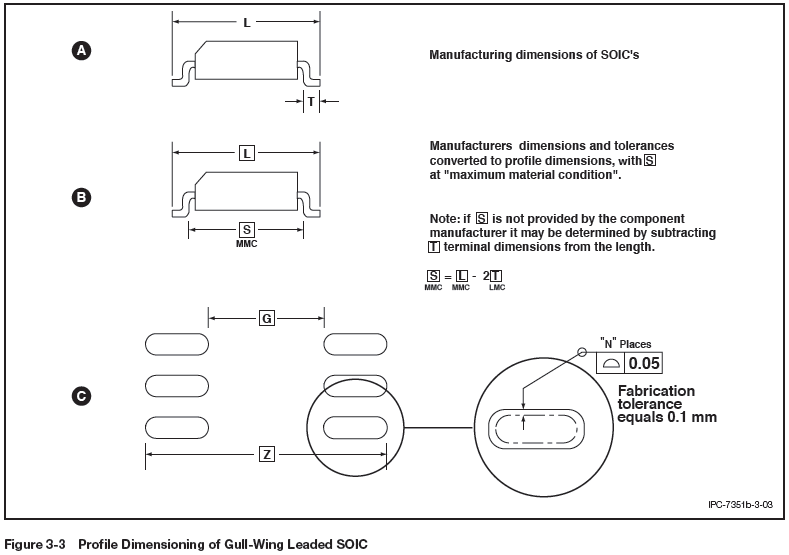

Standards for SMD technology IPC-SM-782, IPC-SM-782A, IPC-7351, IPC-7351A and

IPC-7351B have always promoted Rounded Corner pad shape as the preferred pad

stack. However, Most CAD tools did not support Rounded Rectangle pad shape

until recently both PADS Layout and Altium Designer added this feature to their

PCB library editor.

Here is a picture from the IPC-SM-782A that describes the default pad shape:

However, all component manufacturer recommended footprint patterns recommend a rectangular pad shape. So the great compromise between the world standards and component manufacturers is “Rounded Rectangle” as the default. In the Library Expert program, the user can easily switch pad shape to Oblong, Rectangle or D-Shape but the default installation is now Rounded Rectangle and this will be the recommendation in the upcoming IPC-7351C standard due for release in Q2 2016. It should also be noted that most fabrication and assembly shops prefer Rounded Rectangle pad shape and some say that it is better for lead-free solder attachment. ------------- Stay connected - follow us! https://twitter.com/PCBLibraries" rel="nofollow - X - http://www.linkedin.com/company/pcb-libraries-inc-/" rel="nofollow - LinkedIn |

Replies:

Posted By: matthelm

Date Posted: 07 Nov 2014 at 1:21pm

|

What should be done with larger pads where full radius pads make no sense? (Slugs, large metal parts, etc.) Is there a recommended radius for those? |

Posted By: Tom H

Date Posted: 07 Nov 2014 at 1:38pm

|

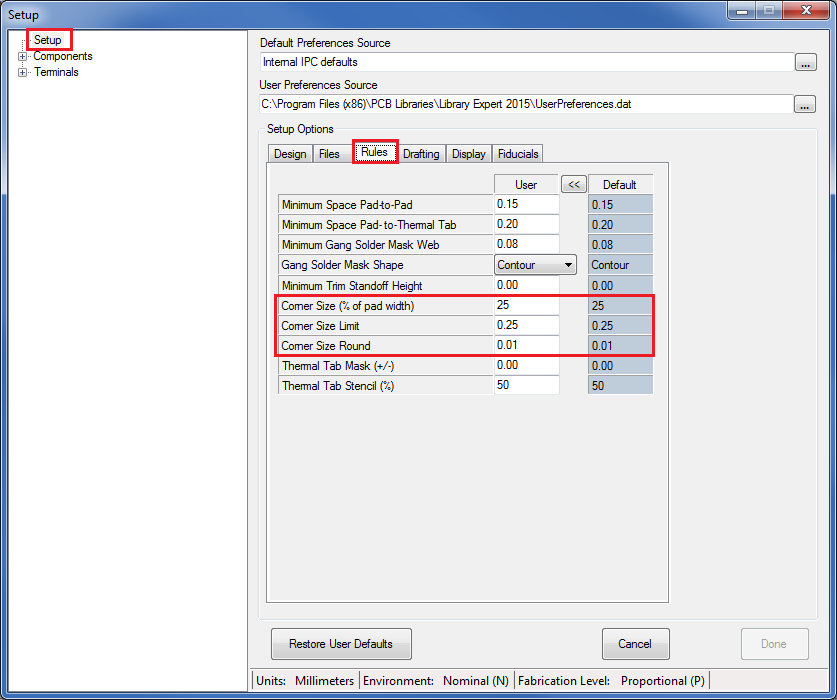

Full Radius = Oblong IPC only preferred Oblong because all CAD tools supported it. Now the standard is Rounded Rectangle instead of Oblong. All SMD pad shapes the used to be Rectangle and now Rounded Rectangle. Here are the Rounded Rectangle default rules (that you can change in User Preferences)

The controls for Rounded Rectangle pad shape are here -

------------- Stay connected - follow us! https://twitter.com/PCBLibraries" rel="nofollow - X - http://www.linkedin.com/company/pcb-libraries-inc-/" rel="nofollow - LinkedIn |

Posted By: 5not4

Date Posted: 18 Nov 2014 at 9:31am

|

Hi Tom. You mention IPC-SM-782(a) as a reference but I can't find anything at IPC for this document. Also, where in the 7351B document does it state that rounded corners are preferred?

|

Posted By: Tom H

Date Posted: 18 Nov 2014 at 10:45am

|

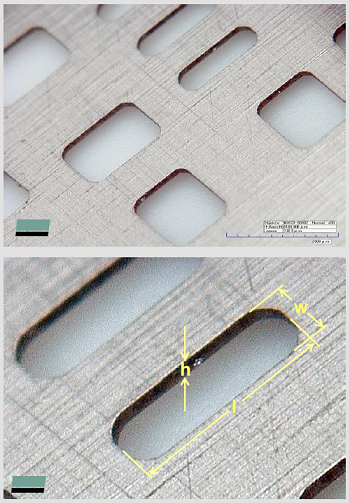

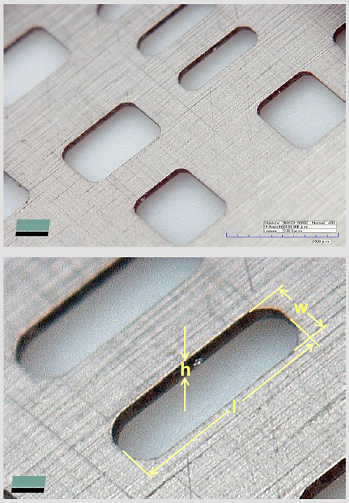

The IPC-SM-782 committee formed in 1985 and released the standard in March 1987 and it lasted 18 years until 2005 when IPC-7351 replaced it. PCB manufacturer's have long recommended Rounded Corner SMD pad shape for several reasons. Better stencil release and paste mask stencil apertures are normally corner radius.

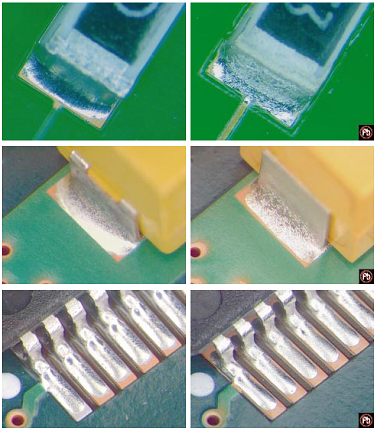

J-STD-001 has illustrations of solder joints of rectangle pads and there is no solder in the rectangle corners after reflow.

IPC-7351 contradicted itself regarding pad shape. The Land Pattern committee always confirmed the preferred use of a rounded pad shape but every picture in the standard illustrated rectangular pad shape. Oblong (full radius) was the preference because many CAD tools did not natively support Rounded Rectangle pad shape in 2005 when the standard was released. This contradiction was finally brought to the attention of the committee after IPC-7351A was released. So IPC had their graphic illustration department change every rectangle pad shape to rounded pad shape in the IPC-7351B release. Here are two of the graphic pictures that were changed, QFP and SOP. QFP -

SOP -

Most of the CAD vendors introduced "Rounded Rectangle" pad shape in their PCB library editors. This was to meet the demand of their customer base who got their information from the manufacturer's that Rounded Rectangle was better for their manufacturing process. Of course this is a decision that every PCB designer needs to discuss with their fabrication and assembly manufacturer's because this is a very controversial subject with various opinions. An example of the controversy is that All component manufacturer datasheets that include a mfr. recommended pattern in the datasheet always recommend a Rectangular pad shape. I have never seen a mfr. recommended pattern with oblong or rounded rectangle pad shape even though that's all IPC recommends. So we recommend that if you do use a mfr. recommended pattern that you add a corner radius to the pad. ------------- Stay connected - follow us! https://twitter.com/PCBLibraries" rel="nofollow - X - http://www.linkedin.com/company/pcb-libraries-inc-/" rel="nofollow - LinkedIn |

Posted By: 5not4

Date Posted: 18 Nov 2014 at 10:45am

|

Found the answer to #1. SM-782 is the precursor to 7351 standard and no longer in print. But I would still like to know where rounded rectangles stated to be preferred in the 7351.

|

Posted By: Tom H

Date Posted: 20 Nov 2014 at 6:22am

|

I just got word from IPC that "Rounded Rectangle" pad shape strengthens the solder joint. This information will be published in the upcoming IPC-7351C standard. ------------- Stay connected - follow us! https://twitter.com/PCBLibraries" rel="nofollow - X - http://www.linkedin.com/company/pcb-libraries-inc-/" rel="nofollow - LinkedIn |

Posted By: 5not4

Date Posted: 24 Nov 2014 at 6:46am

|

Thanks, Tom This is all good information.

|

Posted By: AGONZ67

Date Posted: 24 Nov 2014 at 3:36pm

I suppose if there was ample solder that argument could be made. However in the example pictures it appears even with oblong pads there would not be enough solder to fully cover the pads. Six of one half a dozen of the other.  |

Posted By: eyoung

Date Posted: 18 Oct 2023 at 7:26am

|

Which IPC standard has these specific recommendations for rounded rectangles? |

Posted By: Tom H

Date Posted: 18 Oct 2023 at 8:25am

|

CAD vendors created Rounded Rectangle pad shape. Most component datasheets recommend rectangular pad shape. IPC recommends oblong pad shape. Rounded Rectangle was primarily intended for the pad shape to be similar to the paste mask stencil aperture opening which is created by a laser and has rounded corner openings.  ------------- Stay connected - follow us! https://twitter.com/PCBLibraries" rel="nofollow - X - http://www.linkedin.com/company/pcb-libraries-inc-/" rel="nofollow - LinkedIn |

Posted By: eyoung

Date Posted: 18 Oct 2023 at 8:38am

|

Our organization recently bought the IPC standard 7352 and it does consider rounded rectangle pads advantageous espically for Pb-free soldering processes(relevant to us) in comparison with rectangular pads I cant seem to find where it exactly states that rounded pads strengthens the solder joint, or where these values (below) were determined

Im trying to justify our organization to move towards an update to our procedures to use rounded rectangle pads so that we are up to industry standard. I want to be able to justify this change with a concrete IPC standard , if available. If so, could you point me to the exact one? Or maybe a study that demonstrates these claims. I appreciate your time and attention on this very much |

Posted By: Tom H

Date Posted: 18 Oct 2023 at 9:17am

|

All IPC documents regarding PCB design and land patterns have been downgraded from "Standard" to "Guideline". All new Texas Instruments datasheets provide a recommended solder pattern and the pad patterns have 0.05 mm corner radius. You decide what settings work best for you. The current Footprint Expert default for Maximum Radius is 0.20 mm (not 0.25 mm) but you can change the Maximum value to anything you want. You can also change all pad shapes to be Oblong or Rectangle. Or some component families can have oblong and some rectangle. You need to make your own choices, but I would discuss this with an assembly shop because the pad shape affects that manufacturing process. ------------- Stay connected - follow us! https://twitter.com/PCBLibraries" rel="nofollow - X - http://www.linkedin.com/company/pcb-libraries-inc-/" rel="nofollow - LinkedIn |

Posted By: eyoung

Date Posted: 07 Dec 2023 at 11:29am

|

does PCB Footprint Expert - for Allegro include the new additions and recommendations that have been released in IPC-7352? Our company is considering a footprint/librarian program to help streamline our component creation process. |

Posted By: Tom H

Date Posted: 07 Dec 2023 at 11:36am

|

V23 & the new V24 have IPC-7352 footprint naming convention and an Option file that turns off the Fabrication and Assembly tolerances and updates all negative solder joint goals to 0.00. Note: All Option settings are user definable. ------------- Stay connected - follow us! https://twitter.com/PCBLibraries" rel="nofollow - X - http://www.linkedin.com/company/pcb-libraries-inc-/" rel="nofollow - LinkedIn |