|

|

IPC-7352 strange evolutions |

Post Reply

|

| Author | |

sot23

Active User

Joined: 30 Jun 2022 Status: Offline Points: 17 |

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Topic: IPC-7352 strange evolutions Topic: IPC-7352 strange evolutionsPosted: Yesterday at 8:23am |

|

Hello, my team recently purchased the IPC-7352 released in 2023 and I am currently in the process of studying it to decide whether we should make it our new standard for footprints creation or not. For the moment I must admit that I am not thrilled by what I have read. Some exemples :

My question : what do you all think about 7352 ? I would be very interested in your opinion specifically, Tom H, as I know you are very much involved in the IPC talks (thanks for all your work on that by the way). Is it a good upgrade to 7351B ? Honestly I was hoping for more. But maybe I am a bit to difficult... Sorry if my English is not perfect, as it is not my primary language.

|

|

|

|

|

|

|

|

Tom H

Admin Group

Joined: 05 Jan 2012 Location: San Diego, CA Status: Offline Points: 5967 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: Yesterday at 8:56am Posted: Yesterday at 8:56am |

|

IPC-7351B and IPC-7352 are identical for Surface Mount. No change except the pad stack naming convention added a double 'rr' for Rounded Rectangle pad shape.

IPC-7352 introduced Through-hole technology, but most of the information was extracted from IPC-2221 & IPC-2222. The main thing that was added was the Through-hole land pattern naming convention which we created in 2008 but shelved until 2023. The IPC-735x series misses the mark in several areas. - Solder joint goals 'one size fits all' doesn't produce the best assembly attachment and it doesn't adhere to IPC J-STD-001. Also, the values between density levels is too robust. Most is too Most and Least is too Least. - The naming convention puts the 'pin qty' at the end of the footprint name. This was changed in the IPC-7351C standard that was unanimously approved by the land pattern committee but never got released. - The Zero Component Rotation differs from the standard they replaced - IPC-SM-782 Related posts: |

|

|

|

sot23

Active User

Joined: 30 Jun 2022 Status: Offline Points: 17 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 4 hours 15 minutes ago at 9:05am Posted: 4 hours 15 minutes ago at 9:05am |

|

Thank your for the answer.

"IPC-7351B and IPC-7352 are identical for Surface Mount. No change except the pad stack naming convention added a double 'rr' for Rounded Rectangle pad shape." That is not what I see when I read both documents side by side : Table 3-3 (page 10) of the 7352 specify a Toe calculation for Square ends components with W=<0.5mm that, on the Median footprint, is dependent of the height of the component (which I think totally makes sense when comparing to J-STD-001). This is not the case for the 7351 (table 3-5, page 17). As this height dependency is only for the N footprint, it leads to cases where the N pads are smaller than the L pads, which seems strange. "IPC-7352 introduced Through-hole technology, but most of the information was extracted from IPC-2221 & IPC-2222." The Through hole calculation (4.4.1, table 4-1 and 4-2) is in direct contradiction to the calculation in IPC 2222 (Table 9-5). Or I am having big trouble understanding theses tables. Theses are mostly the points that confuses me. Thank you for the linked posts. It is very interesting to know the history behind these standards.

|

|

|

|

Tom H

Admin Group

Joined: 05 Jan 2012 Location: San Diego, CA Status: Offline Points: 5967 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 3 hours 4 minutes ago at 10:16am Posted: 3 hours 4 minutes ago at 10:16am |

|

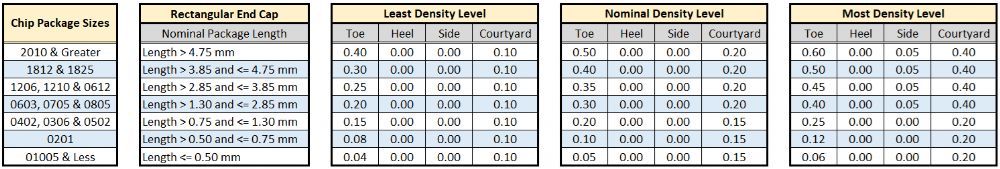

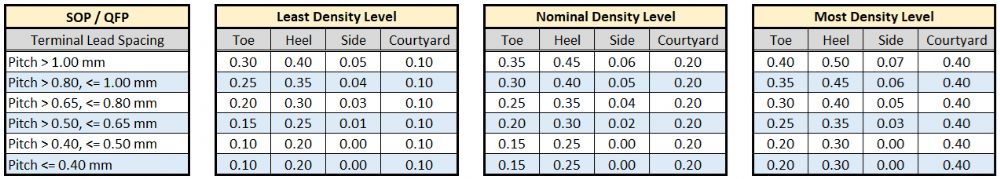

The unreleased IPC-7351C had new solder joint goal tables for Gull Wing and Rectangular or Square End Cap packages.

The Square End Cap solder joint goals need to have unique Toe values for every chip size.  The Gullwing terminal lead needs a different toe goal for every pin pitch.  SOP/QFP Table:  |

|

|

|

Post Reply

|

|

| Tweet |

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |