|

|

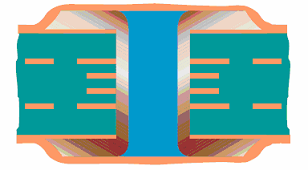

Thermal Relief for SMD components |

Post Reply

|

| Author | |

DaveCowl

Advanced User

Joined: 18 Oct 2012 Location: Santa Clara, CA Status: Offline Points: 161 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Thermal Relief for SMD components Topic: Thermal Relief for SMD componentsPosted: 10 Jul 2013 at 2:33pm |

|

So we are all familiar with Thermal Relief for through hole parts. What about SMD? While it perhaps doesn't have a huge impact on the reflow process since the board is fully heated (?!?), it can certainly make rework difficult with regard to part removal and replacement. Linear Tech encourages the use of solid planes and effectively therefore solder mask defined pads for their BGA and LGA modules. What about other BGAs? Would using solder mask defined pads be problematic for BGA parts? IIRC, the ball encompasses the pad, which would not happen for solder mask defined pads. On the plus side, GND floods would have much better connectivity without thermal relief, especially in cases where you are reduced to 1 or 2 spokes due to other routing near the pad. Any thoughts on the pros and cons of thermal relief for BGA and other SMD parts? Cheers! Dave. |

|

|

|

|

|

Tom H

Admin Group

Joined: 05 Jan 2012 Location: San Diego, CA Status: Offline Points: 5718 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Jul 2013 at 5:20pm Posted: 10 Jul 2013 at 5:20pm |

|

I only use thermal relief on SMD when via is in pad.

If the via has a 0.25 mm space between the via and the SMD pad, the trace that connects them is the Thermal Relief. |

|

|

|

Artwork Master ITALY

Active User

Joined: 12 Mar 2012 Location: Milano ITALY Status: Offline Points: 43 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jul 2013 at 4:46am Posted: 11 Jul 2013 at 4:46am |

|

Hey Tom, can You add a picture of "thermal relief on SMD when via is in pad" ????

a picture is better than words to understand the concept... thanks. Livio |

|

|

|

DaveCowl

Advanced User

Joined: 18 Oct 2012 Location: Santa Clara, CA Status: Offline Points: 161 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jul 2013 at 10:55am Posted: 11 Jul 2013 at 10:55am |

|

On an HDI board with GND flood on the top layer, the GND pins on SMD parts do not have vias - they just connect to the plane.

For the LT parts you typically have the Vin and Vout (and GND) in pour as well, and the BGA balls are in x/y arrays. So they are connected to the planes on the top layer. Certainly for pins that have a trace to a via this is not a concern - I am interested in pins that contact flood, pour or planes on the component layer, usually for GND and VCC pins. Thoughts? Cheers!

|

|

|

|

Tom H

Admin Group

Joined: 05 Jan 2012 Location: San Diego, CA Status: Offline Points: 5718 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 Jul 2013 at 12:13pm Posted: 11 Jul 2013 at 12:13pm |

|

At Artwork Master in Italy -

The via-in-pad is when a SMT pad has a via in it and the GND / VCC connection is on the inner layer just like a normal through-hole component. I always "Flood Over" every via in a PCB layout expect those that are via-in-pad will have a thermal relief. The via-in-pad vias have to be specially marked on the fabrication drawing as they need to be plated, plugged, capped, surface finish and planerized flat so that you cannot tell if there is a hole or not.  |

|

|

|

Post Reply

|

|

| Tweet |

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |