|

|

IPC-7351 Collapsing and Non-Collapsing BGA Balls |

Post Reply

|

| Author | |

Tom H

Admin Group

Joined: 05 Jan 2012 Location: San Diego, CA Status: Offline Points: 5718 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: IPC-7351 Collapsing and Non-Collapsing BGA Balls Topic: IPC-7351 Collapsing and Non-Collapsing BGA BallsPosted: 07 Apr 2024 at 1:31pm |

|

IPC has a rule for BGA pad size tolerances. They take a Nominal Ball and reduce or increase the pad size by a percentage, then add a pad size tolerance (variation). IPC-7351 recommends using the Maximum Material Condition of the Variation.

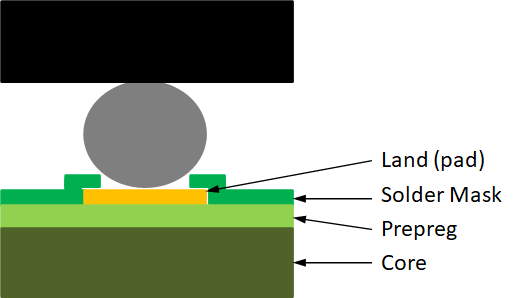

All BGA balls collapse. Non-collapsing BGA balls are created by the PCB librarian by solder mask defined pads or making the pad size larger than the Ball. Collapsing Ball. Non-Collapsing Ball defined by Solder Mask. IPC-7351 BGA tables for pad size reduction for collapsing balls and pad size increase for non-collapsing balls. The pad size increase is normally used for fine pitch BGA's that require via-in-pad technology for fanout. There are 3 Density Levels A, B and C that indicate the percentage amount for pad size calculation.  |

|

|

|

|

|

Tom H

Admin Group

Joined: 05 Jan 2012 Location: San Diego, CA Status: Offline Points: 5718 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 07 Apr 2024 at 1:39pm Posted: 07 Apr 2024 at 1:39pm |

|

The Solder Mask Defined BGA pad helps secure the pad to the prepreg. This helps during drop tests.

|

|

|

|

Post Reply

|

|

| Tweet |

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |