|

|

Max Pin Tolerance Exceeds Calculated Pad Size |

Post Reply

|

| Author | |

Michael Ramonette

New User

Joined: 13 Dec 2016 Status: Offline Points: 4 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Max Pin Tolerance Exceeds Calculated Pad Size Topic: Max Pin Tolerance Exceeds Calculated Pad SizePosted: 18 Aug 2023 at 10:19am |

|

A nominal footprint that was

created with the parts calculator with a pin max width of 0.35 mm and a minimum width of 0.30.

The concern I have is the pad is calculated at 0.32 mm and if we get a batch of parts that are created at the max tolerance the pin will overhang the pad on the b measurement. Is this correct or am I missing something? What do I tell my Engineers?

|

|

|

|

|

|

Tom H

Admin Group

Joined: 05 Jan 2012 Location: San Diego, CA Status: Offline Points: 5718 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Aug 2023 at 12:21pm Posted: 18 Aug 2023 at 12:21pm |

|

What version of Footprint Expert are you using?

What is the component family of the footprint you're creating? |

|

|

|

Michael Ramonette

New User

Joined: 13 Dec 2016 Status: Offline Points: 4 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Aug 2023 at 2:36pm Posted: 18 Aug 2023 at 2:36pm |

|

16 pin QFN with pad

I had my librarian re-create it with a newer version of library expert with the same results.

MAX8556ETE+ |

|

|

|

Tom H

Admin Group

Joined: 05 Jan 2012 Location: San Diego, CA Status: Offline Points: 5718 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Aug 2023 at 2:55pm Posted: 18 Aug 2023 at 2:55pm |

|

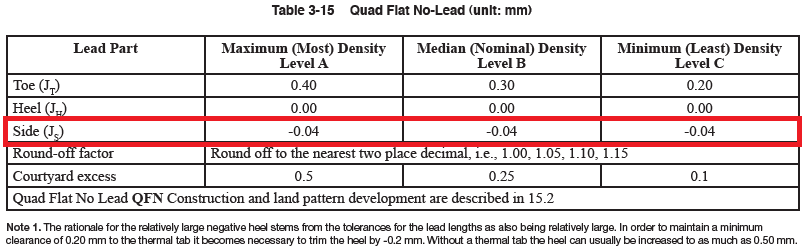

The Side solder joint goal for the "Flat No-Lead (Side)" is set to -0.04.

If this is troubling you and your engineers then do this. Go to "Tools > Options > Terminals > Surface Mount > Flat No-Lead (Side) > Side goal" and change the value from -0.04 to -0.02 and your pad width will recalculate to 0.36 mm All the values in Footprint Expert are editable. If you don't like a value set forth in the IPC-7351B standard then change it. Here is the Flat No-Lead Table 3-15 in IPC-7351B (and an explanation of the negative solder joint goals:  |

|

|

|

Michael Ramonette

New User

Joined: 13 Dec 2016 Status: Offline Points: 4 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Aug 2023 at 4:28pm Posted: 18 Aug 2023 at 4:28pm |

|

Does this violate IPC-7351B or C?

We have an IPC library and are contently questioned on parts created for one reason or another. If it does violate IPC suggestions I will be creating this as alternate part.

|

|

|

|

Tom H

Admin Group

Joined: 05 Jan 2012 Location: San Diego, CA Status: Offline Points: 5718 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Aug 2023 at 4:59pm Posted: 18 Aug 2023 at 4:59pm |

|

IPC-7351C was canceled and replaced with IPC-7352 which includes through-hole technology.

IPC-7352 is NOT a Standard. It's a Generic Guideline for Land Pattern Design. There's no such thing as violating a Guideline. A Guideline is a suggestion or recommendation. You mentioned that the default side solder joint goal for a Flat No-Lead QFN is 0.03 mm smaller than the maximum terminal lead width. Tell your engineers that you're adjusting the "Guideline" by less than 1 mil because you're paranoid that the pad width is too small. The main reason why the Guideline suggests a -0.04 mm side goal is because of the 0.40 mm pin pitch QFN where the pad sides would be too close together and violate your minimum pad to pad spacing. Also, you can't run a trace between a 0.50 mm pin pitch QFN. So the maximum lead hanging over the pad slightly won't affect anything. |

|

|

|

dramos

Advanced User

Joined: 18 Feb 2021 Status: Offline Points: 61 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Aug 2023 at 12:13pm Posted: 21 Aug 2023 at 12:13pm |

|

Dear Michael,

Which values are you using for fabrication/assembly tolerances in this case? The default values? 0.00 mm? Regards. David

|

|

|

|

Tom H

Admin Group

Joined: 05 Jan 2012 Location: San Diego, CA Status: Offline Points: 5718 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Aug 2023 at 12:34pm Posted: 21 Aug 2023 at 12:34pm |

|

0.00 Fabrication & Assembly Tolerances are the new norm per IPC-7352.

But all the negative solder joint goals are 0.00 too. There is an IPC-7352.opt file that updates all the options to do this. However, if you open the IPC-7352.opt file, don't forget to save it under a different name before you start editing it because it will be overwritten with a new installation. |

|

|

|

Post Reply

|

|

| Tweet |

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |