|

|

Proportional Through-hole Padstacks |

Post Reply

|

Page 123 4> |

| Author | |

Nick B

Admin Group

Joined: 02 Jan 2012 Status: Offline Points: 1985 |

Post Options Post Options

Thanks(3) Thanks(3)

Quote Quote  Reply Reply

Topic: Proportional Through-hole Padstacks Topic: Proportional Through-hole PadstacksPosted: 14 Mar 2012 at 3:22am |

|

Here is the latest Through-hole Padstacks file - Updated 8-9-12

(you need to be logged in, registration is absolutely free!)

|

|

|

|

|

|

|

|

Chris

Active User

Joined: 06 Mar 2012 Location: UK (Cheshire) Status: Offline Points: 11 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Mar 2012 at 4:29am Posted: 14 Mar 2012 at 4:29am |

|

Thanks very much.

|

|

|

|

Nightwish

Active User

Joined: 20 Feb 2012 Location: Shanghai China Status: Offline Points: 33 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 14 Mar 2012 at 6:56am Posted: 14 Mar 2012 at 6:56am |

|

Thanks a lot for sharing this with us

|

|

|

|

Nick B

Admin Group

Joined: 02 Jan 2012 Status: Offline Points: 1985 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Mar 2012 at 3:38am Posted: 15 Mar 2012 at 3:38am |

|

Updated on March 15, 2012 - see link in original post for latest version.

|

|

|

|

IanOnBass

Advanced User

Joined: 15 Mar 2012 Location: UK Status: Offline Points: 99 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Mar 2012 at 2:08pm Posted: 15 Mar 2012 at 2:08pm |

|

Excellent resource. Thanks for sharing.

|

|

|

|

RLS2004

Advanced User

Joined: 26 Jan 2012 Location: Seattle,WA Status: Offline Points: 51 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 15 Mar 2012 at 2:37pm Posted: 15 Mar 2012 at 2:37pm |

|

Thanks for updating TH Padstacks.

|

|

|

|

Taylor_RS

New User

Joined: 16 Mar 2012 Location: Michigan Status: Offline Points: 2 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 16 Mar 2012 at 5:56am Posted: 16 Mar 2012 at 5:56am |

|

Thanks a ton!

|

|

|

|

Artwork Master ITALY

Active User

Joined: 12 Mar 2012 Location: Milano ITALY Status: Offline Points: 43 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Mar 2012 at 9:51am Posted: 18 Mar 2012 at 9:51am |

|

Great work!

|

|

|

|

Nick B

Admin Group

Joined: 02 Jan 2012 Status: Offline Points: 1985 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Mar 2012 at 2:40am Posted: 20 Mar 2012 at 2:40am |

|

The link above was updated again: Updated the Thermal Spoke Width calculations for Plated Through Hole padstacks The new improved formula is: Spoke Width = 75% of Plane Anti-pad divided by 4 |

|

|

|

Tom H

Admin Group

Joined: 05 Jan 2012 Location: San Diego, CA Status: Offline Points: 6002 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 Mar 2012 at 11:15am Posted: 20 Mar 2012 at 11:15am |

|

Here is the "Proportional Through-hole Padstack" Mathematical Model data:

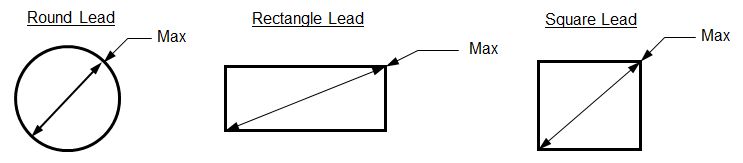

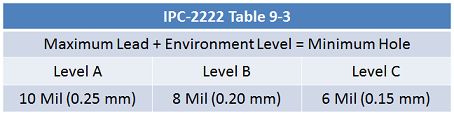

The first column is the Maximum Component Lead Size and it is determined by -  The second column is the Finished Hole Size and it is determined by adding 8 mil (0.2 mm) to the Maximum Lead Size in the first column. This is the "Nominal" Lead to Hole calculation as seen in the chart from the IPC-2222 standard.  The next 5 columns are the Pad Sizes for all the layers and they are the same value across all the rows. The Pad Size starts out using the IPC-2221 nominal annular ring requirements of 10 mil (0.25 mm) or the Pad is 20 mil (0.5 mm) larger than the hole size. Then, as the hole size gradually gets larger, the pad annular ring grows "Proportionally" larger in increments of 1 mil (0.025 mm). The primary theory is that the hole size gets larger to accommodate a larger component lead. Larger component leads are created to carry additional current or because the component size is large and needs stronger support (more solder). The Plane Anti-Pad Clearance is derived from the Hole Size and it remains relatively constant because it has nothing to do with supporting large components. It's simply a clearance from the hole to improve the PCB manufacturing yields. The minimum annular ring of the Plane Anti-Pad is 15 mil (0.35 mm) for holes intended for component leads. As the hole size grows in size, the Plane Anti-Pad stays somewhat constant but it does slightly grow as the hole size grows to keep a safe distance from higher voltage currents that larger holes can carry. The Thermal Relief is a simple formula - The ID is 20 mil (0.5 mm) larger than the Hole Size The OD is the same value as the Anti-pad The Spoke Width = Anti-pad X 75% divided by 4 spokes, the calculated spoke width X 4 = Hole Size or slightly larger than the hole Edited by Tom H - 20 Mar 2012 at 11:19am |

|

|

|

Post Reply

|

Page 123 4> |

| Tweet |

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |