|

|

Footprints For Similar Parts, Different Tolerances |

Post Reply

|

| Author | |

ckhalleran

Active User

Joined: 22 Nov 2017 Status: Offline Points: 26 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Footprints For Similar Parts, Different Tolerances Topic: Footprints For Similar Parts, Different TolerancesPosted: 21 Sep 2021 at 1:08pm |

|

Previously I made just one footprint for a specific size of ceramic SMT cap (I used what appeared to be the tallest cap in that size). Looking at one of Tom's posts about different heights and tolerances on SMT chip parts... how it affects the footprint... and that you don't want to cause tombstoning by getting too much solder paste on a smaller part?

Anyway, it appears that the tolerance does not make a difference in the footprint names (or their descriptions)... so if you made a footprint for an AVX cap (1812 with X7R dielectric), and then made another footprint for AVX cap (1812 with COG dielectric)... even if the height was the same, if they have different tolerances, the pad sizes will be different, but the footprint name would be the same. If a person was to create multiple 1812 cap footprints, and the only thing that was different was the tolerances... you might have 4 mils longer distances between toes, 2 mils shorter distance between heels, and 8 mils greater pad width. So if you DO actually have multiple footprints for the same SMT cap size, how do you differentiate between those footprints? You'd have to give then a different name? that uses the pad dimensions maybe? Regards, Chris

|

|

|

|

|

|

|

|

feynman

Active User

Joined: 06 Feb 2020 Status: Offline Points: 12 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Sep 2021 at 1:45pm Posted: 21 Sep 2021 at 1:45pm |

|

I wouldn't bother too much about different tolerances. If a footprint works for one tolerance, it is very likely that it will also work for another tolerance. For sizes of 0603 and smaller, however, I would simply ask an assembler for a well-functioning footprint, anyway.

|

|

|

|

Tom H

Admin Group

Joined: 05 Jan 2012 Location: San Diego, CA Status: Offline Points: 5993 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Sep 2021 at 1:46pm Posted: 21 Sep 2021 at 1:46pm |

|

Package tolerances are a problem in maintaining a minimal footprint library. You want to use the same 1206 chip capacitor footprint for multiple vendors. Everyone has the same issue.

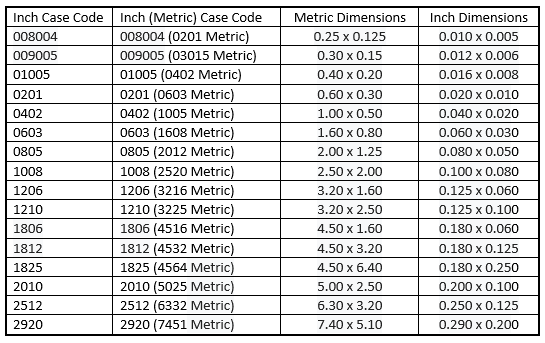

You should select the average tolerance for each chip package. Choose vendors that fit into those tolerances but have your own personal tolerance that you can round up or down to fit into your tolerances. Example: If you have tolerances like this - +/- 0.10, +/- 0.15, +/- 0.20 then the average in +/- 0.15. You can take the 0.10 and round up and the 0.20 and round down. It's a fact that every component manufacturer tries their best to deliver their packages in the Nominal Material Condition and then the tolerance is unnecessary. But to be on the safe side, create an acceptable tolerance table. Then you need to deal with manufacturer's that have slightly different package dimensions. And the Package Height is another factor. Here's a Chip table with common dimensions. Avoid using manufacturers that have different dimensions or create a special footprint for them.  |

|

|

|

ckhalleran

Active User

Joined: 22 Nov 2017 Status: Offline Points: 26 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Sep 2021 at 6:04am Posted: 22 Sep 2021 at 6:04am |

|

Thanks for your replies. If most of our caps are 0805 and bigger, there's less chance for tombstoning, and it might not matter if I stuck with the higher tolerance found on most of those caps (rather than averaging)?

|

|

|

|

Post Reply

|

|

| Tweet |

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |