|

|

Proportional Through-hole Padstacks |

Post Reply

|

Page <1234> |

| Author | |

jameshead

Expert User

Joined: 20 Mar 2012 Location: Oxfordshire, UK Status: Offline Points: 576 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Aug 2012 at 8:49am Posted: 21 Aug 2012 at 8:49am |

|

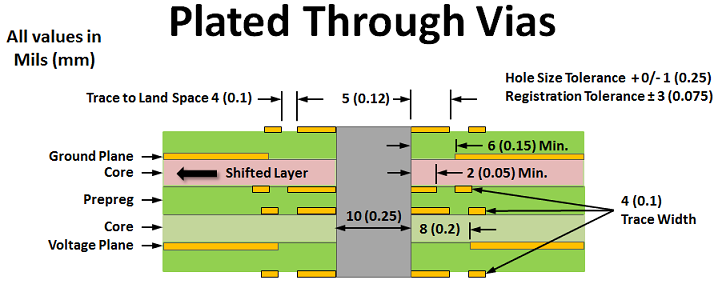

I've mentioned this on the SMART group e-mail list as well. A good PCB fabricator mentioned that using laser direct imaging can accommodate a 0.075 mm radial annular ring for drilled hole diameter (not finished hole diameter) on an outer layer for "no breakout" condition but would recommend 0.125 mm radial for inner layers in the same pad stack.

|

|

|

|

|

|

|

|

Tom H

Admin Group

Joined: 05 Jan 2012 Location: San Diego, CA Status: Offline Points: 6021 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 Aug 2012 at 9:10am Posted: 21 Aug 2012 at 9:10am |

|

I have heard from Gary Ferrari at this years IPC APEX conference that the IPC-2221 and 2222 are being overhauled and will be released before the next IPC APEX conference in San Diego, CA in early 2013. But I don't see any release notification here - http://www.ipc.org/CommitteeDetail.aspx?Committee=D-31B

All I can say is that the Proportional Via Padstacks have been used in production by CADPRO on over 2,000 PCB layouts and Wind River (now Intel) and all their PCB Layouts before we released it to the public in 2004 via PCB Libraries, Inc. No fabrication shop or EE engineer has ever complained of problems and many of the designs we did went into high volume production. Download the paper on PCB Design Optimization Starts in the CAD Library - Here is a picture from the presentation regarding inner layer shifting & annular ring -  |

|

|

|

plinder

Advanced User

Joined: 13 Apr 2012 Location: Vermont Status: Offline Points: 141 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Oct 2012 at 10:43am Posted: 01 Oct 2012 at 10:43am |

|

The Footprint names for Mounting Holes look different than the last version of LP Wizard. What naming convention do you plan on carrying forward for Mounting Holes?

|

|

|

|

Tom H

Admin Group

Joined: 05 Jan 2012 Location: San Diego, CA Status: Offline Points: 6021 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Oct 2012 at 11:54am Posted: 01 Oct 2012 at 11:54am |

|

Mounting Holes will not make it into the PCB Footprint Expert.

All ANSI and ISO Mounting Holes will be available in every CAD format for free download soon. |

|

|

|

Vladimir.Stoyanov

New User

Joined: 22 Mar 2012 Location: Bulgaria Status: Offline Points: 12 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 01 Oct 2012 at 11:41pm Posted: 01 Oct 2012 at 11:41pm |

|

Hi Tom,

|

|

|

|

Tom H

Admin Group

Joined: 05 Jan 2012 Location: San Diego, CA Status: Offline Points: 6021 |

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 02 Oct 2012 at 7:23am Posted: 02 Oct 2012 at 7:23am |

|

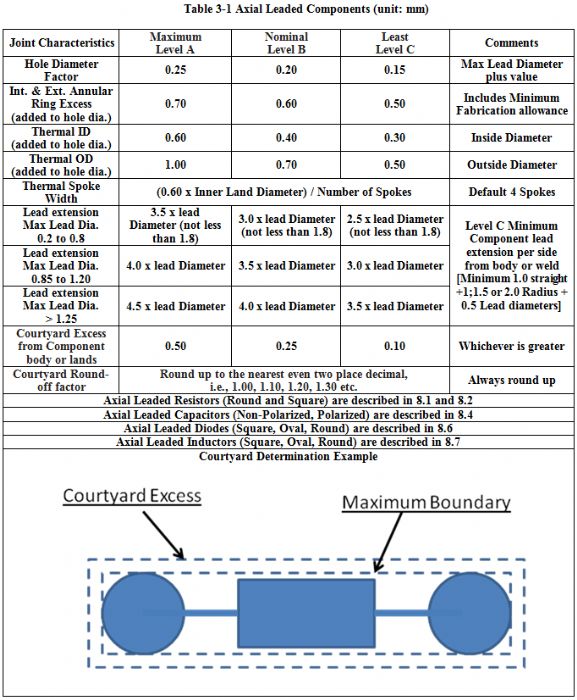

The PCB Footprint Expert supports the unreleased IPC-7251 through-hole standard but I prefer "Proportional Padstacks" because they cover all 3-Tiers.

The IPC-7251 has fixed annular rings for each tier, regardless of the hole size. The Proportional Padstack annular ring gradually increases with the hole size. So small holes use the Least annular ring, medium size holes use Nominal annular ring and larger hole sizes use the Most annular ring. Then there's a point where the hole size is larger than 2 mm (80 mils) and the annular ring gradually gets even larger than the IPC-7251 standard. So Proportional Padstacks meet or beat IPC-7251. The theory is simple. If a through-hole component lead has a large diameter it's for a reason. It might need to carry a lot of current or the component may be tall and requires stability or the component may be heavy and require support. All of these reasons require a larger annular ring which allows more solder. Example: in the case of a large component lead that carries current, this will increase the temperature as the board functions and the large annular dissipates heat. If you use the Least Environment with the small annular ring, it's less solder and less heat dissipation. Note: I've used the Proportional Padstacks on over 1,000 PCB layout designs for both prototype and production boards and never had a manufacturing problem or a field problem. It's proven to be a very reliable padstack. Here is the IPC-7251 table for Axial Lead components:  |

|

|

|

Vladimir.Stoyanov

New User

Joined: 22 Mar 2012 Location: Bulgaria Status: Offline Points: 12 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 Oct 2012 at 11:49pm Posted: 02 Oct 2012 at 11:49pm |

|

Dear Tom,

I made terrible mistake - for PTH I use Most level, not Least. Even with this level I receive a mumble from our plants. For PTH footprints I use Excel table from PCB Matrix, but it is quite old. Do you have an update of this table? Thanks a lot! |

|

|

|

Tom H

Admin Group

Joined: 05 Jan 2012 Location: San Diego, CA Status: Offline Points: 6021 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Oct 2012 at 7:01am Posted: 03 Oct 2012 at 7:01am |

|

All of the latest updated tables, charts and rules are for free download here - http://www.pcblibraries.com/forum/pcb-library-construction-guidelines_forum30.html

Or here - |

|

|

|

Vladimir.Stoyanov

New User

Joined: 22 Mar 2012 Location: Bulgaria Status: Offline Points: 12 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 Oct 2012 at 9:46pm Posted: 03 Oct 2012 at 9:46pm |

|

IPC-7251_Padstack_Charts.xls

Dear Tom, Now I see that I can attach a file. I just asked you for update of this table. I don't want to use Least neither Nominal level for PTH. Can you help me? Kind regards, |

|

|

|

Nick B

Admin Group

Joined: 02 Jan 2012 Status: Offline Points: 1985 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 04 Oct 2012 at 3:26pm Posted: 04 Oct 2012 at 3:26pm |

|

Please download the latest PTH Padstack Reference Calculator from HERE.

|

|

|

|

Post Reply

|

Page <1234> |

| Tweet |

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |