Thermal Pad Issue

Printed From: PCB Libraries Forum

Category: PCB Footprint Expert

Forum Name: Questions & Answers

Forum Description: issues and technical support

URL: https://www.PCBLibraries.com/forum/forum_posts.asp?TID=3541

Printed Date: 26 Feb 2026 at 5:45am

Topic: Thermal Pad Issue

Posted By: m.elsayed

Subject: Thermal Pad Issue

Date Posted: 14 Sep 2025 at 5:56pm

|

I can adjust Thermal Pad by this parameter, but when open in Altium gives wrong value. Can have more explain how to adjust this? uploads/11979/nm.jpg" rel="nofollow - uploads/11979/nm.jpg uploads/11979/exposed_pad_paste_mask=-3.2_same_as_size.jpg" rel="nofollow - uploads/11979/exposed_pad_paste_mask=-3.2_same_as_size.jpg uploads/11979/ep.fpx" rel="nofollow - uploads/11979/ep.fpx |

Replies:

Posted By: Tom H

Date Posted: 14 Sep 2025 at 6:15pm

|

80% Paste Mask Reduction will not give you a Checker Board Pattern. 80% Paste Mask Reduction will provide a single paste mask aperture. 70% is the highest Paste Mask Reduction to generate a Checker Board Pattern. ------------- Stay connected - follow us! https://twitter.com/PCBLibraries" rel="nofollow - X - http://www.linkedin.com/company/pcb-libraries-inc-/" rel="nofollow - LinkedIn |

Posted By: m.elsayed

Date Posted: 14 Sep 2025 at 9:48pm

|

i have attached fpx, can please we have explain on it , if 80% not applicable why tool not block user , rather than get wrong values, please add more details for this point, when apply 70 % what values should appears in Altium

|

Posted By: Tom H

Date Posted: 15 Sep 2025 at 7:29am

|

You must consider all the rules. You have a Minimum Paste Mask web set to 0.20 mm. You need to keep the Thermal Pad Paste Mask 0.10 mm indented from the pad edge. 80% is doable however, you're not going to get a Checker Board Pattern. Many users set Thermal Pad Paste Mask to 100% and allow the Assembly Shop Stencil Mfr. design the paste mask reduction. All we're saying is that we found out that 70% is the highest you can go a still get a Checker Board Pattern. We're not going to limit the software program and not allow 80%. If you're not educated on the mathematics of paste mask reduction, and the consequences of your Option settings, that's not our responsibility. It's trial and error. ------------- Stay connected - follow us! https://twitter.com/PCBLibraries" rel="nofollow - X - http://www.linkedin.com/company/pcb-libraries-inc-/" rel="nofollow - LinkedIn |

Posted By: m.elsayed

Date Posted: 16 Sep 2025 at 5:14am

|

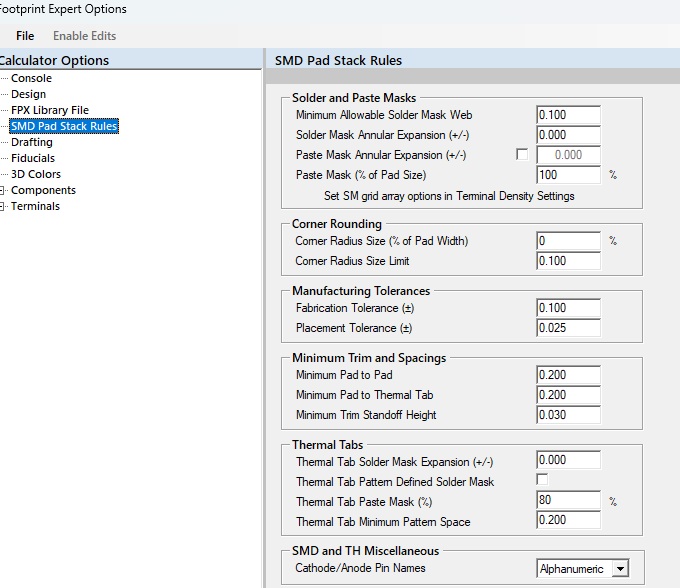

Thanks alot Tom for your support and great help the purpose of question is to get understand the information from expert one like you and know how it works and check what issue on configuration or setting i did can find screen below for my settings , and help  |

Posted By: Tom H

Date Posted: 16 Sep 2025 at 7:47am

|

Footprint Expert had the default Thermal Pad Paste Mask Reduction setting at 50% for many years from 2004 - 2016. We bumped it up to 60% default after helping IPC develop the IPC-7093A standard in 2017. For many years we set the Thermal Pad Paste Mask reduction should be between 40 - 60% with 70% being the limit to accommodate both the Thermal Pad Minimum Space (between checkerboard patterns) and the paste mask apertures. You have to understand the mathematics involved in paste mask reduction and the minimum aperture spacing rule. You do the math and you'll see that everything works accordingly. Take any pad and reduce the size by 80% and see the results. ------------- Stay connected - follow us! https://twitter.com/PCBLibraries" rel="nofollow - X - http://www.linkedin.com/company/pcb-libraries-inc-/" rel="nofollow - LinkedIn |

Posted By: m.elsayed

Date Posted: 17 Sep 2025 at 1:46am

| Thanks alot for your support |