IPC-7351 Placement Tolerance Setting

Printed From: PCB Libraries Forum

Category: PCB Footprint Expert

Forum Name: Questions & Answers

Forum Description: issues and technical support

URL: https://www.PCBLibraries.com/forum/forum_posts.asp?TID=1733

Printed Date: 16 Feb 2026 at 2:56pm

Topic: IPC-7351 Placement Tolerance Setting

Posted By: drj-bbe

Subject: IPC-7351 Placement Tolerance Setting

Date Posted: 15 Jul 2015 at 7:36pm

|

Hello,

For placement tolerance below, it means tolerance for component placed by SMT pick&place machine, right? Why the default accuracy is so high 0.025mm? We used FUJI AIM machine which placement accuracy is 0.04mm.

|

Replies:

Posted By: Tom H

Date Posted: 16 Jul 2015 at 7:54am

|

We (PCB Libraries, Inc.) and IPC agrees with you too. We're working on the new IPC-7351C and we removed the manufacturing tolerances from the standard mathematical model. In our last committee meeting at IPC APEX is was voted to remove the manufacturing tolerances but we need to simulate the new math on a variety of components and compare the results. This update will be reflected in V2016 Library Expert after we run tests for the next few months. But it's OK for you to change the manufacturing tolerance in the current Library Expert. It's a User Definable setting. I would also make the fabrication tolerance 0 because every fabrication shop swells the outer layer etch to compensate for their etching process tolerance. There is no need for double tolerance.

------------- Stay connected - follow us! https://twitter.com/PCBLibraries" rel="nofollow - X - http://www.linkedin.com/company/pcb-libraries-inc-/" rel="nofollow - LinkedIn |

Posted By: drj-bbe

Date Posted: 16 Jul 2015 at 6:18pm

|

Many thanks for your explanation. |

Posted By: dramos

Date Posted: 10 Feb 2023 at 2:06am

|

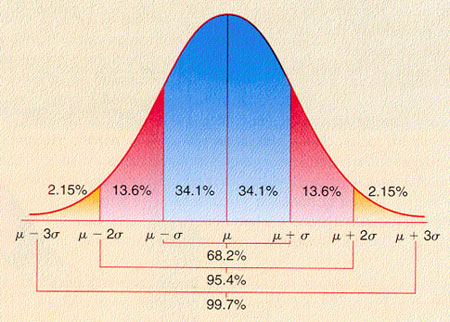

Hi to all, I reopen this threat because the new release of IPC-7352 changes the fabrication tolerances and the placement tolerances to 0.00. Due to this the negative values of the solder joints change to 0.00, as well. I can understand the reason to modify the fabrication tolerance value, it has a lot of sense. The pcb manufacturer applies a correction factor to the pcb due to the etching. Creating a footprint with a fabrication tolerance is to apply twice this tolerance. My question is related to the placement tolerance. Untill now this value was 0.025mm and I cannot understand the reason to modify it to 0.00. For example if a P&P machine has an accuracy of +/-50um (3 sigma), assuming that the component placement is a normal distribution  I think that it means that:

So the placement tolerance of +/- 0.025 mm is not a value far from the reality. Many thanks for help to all of you. Regards. David

|

Posted By: Tom H

Date Posted: 10 Feb 2023 at 11:43am

|

Today's pick & place machines have a tolerance of +/- 0.01 mm. How old is the image that you posted? The V23 footprint expert allows the user to edit that assembly tolerance to match the age of the machines you use. However, the pad stack calculations are so subtle that the difference between 0.025 assembly tolerance and 0.00 is too small to be concerned. ------------- Stay connected - follow us! https://twitter.com/PCBLibraries" rel="nofollow - X - http://www.linkedin.com/company/pcb-libraries-inc-/" rel="nofollow - LinkedIn |