|

|

Footprint for Molded Body |

Post Reply

|

| Author | |

JJonas

Advanced User

Joined: 21 Apr 2014 Status: Offline Points: 113 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Footprint for Molded Body Topic: Footprint for Molded BodyPosted: 25 Aug 2014 at 5:32pm |

|

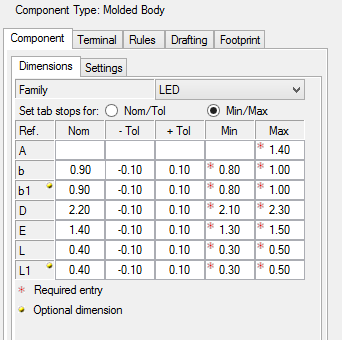

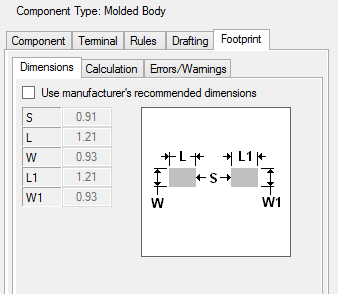

I am not 100% sure, but it seems that footprint is not correctly generated for molded body packages. In my example, b and b1 is set to be max 1 mm, however, W and W1 is calculated to be only 0.93, why not >=1?

|

|

|

|

|

|

|

|

Tom H

Admin Group

Joined: 05 Jan 2012 Location: San Diego, CA Status: Offline Points: 6020 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 Aug 2014 at 6:57pm Posted: 25 Aug 2014 at 6:57pm |

|

The answer to your question is that the "Side" solder joint goals for the pad width calculation are equal to or less than the Max Lead Width. This is correct according to the IPC-7351 solder joint goal chart for the "Inward L-Bend" component lead. But you have access in the User Preferences to change that value. That's the beauty of the Professional version. Also, I would remove the redundant "b1" and "L1" component dimensions. They are strictly for when Pin 2 is a different size. If Pin 1 and 2 are identical there is no need for "b1" and "L1" component dimensions. Also, in the Footprint Tab if the component mfr. provides a recommended patter, I often enter those dimensions here and then see the Viewer for the component Lead on top of pad to visualize the solder joint. But there is the Calculation Tab that provides all the Toe, Heel and Side Min. & Max. goals. |

|

|

|

Post Reply

|

|

| Tweet |

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |